Rubber is a versatile material crucial to the oil and gas industry, coming in various forms for...

Shock absorbers eliminate impact loads for offshore wind

The conditions that offshore wind turbine installation teams and vessels face can be grueling. High winds, heavy loads and rough seas make for tricky waters to complete a successful installation. A common challenge facing these installation teams, is the need to work around the clock to successfully install wind turbines in a constrained time period. Waiting for weather windows is no longer an economical option, meaning continuing the strenuous process of installation regardless of the harsh offshore conditions. Key structural components are therefore under threat of being damaged during installation, as heavy loads and strong forces are combined with the unpredictable installation environment.

A key part of the installation process of several windfarms is the lifting, sliding and connecting of the transition piece onto the monopile. This sequence of events can be made difficult by high seas, strong winds and harsh offshore conditions. So, when there are an abundance of material and product options, how do you know which one to choose?

Making the right material choice

Making the right material choice

Every engineered solution is carefully designed and created to use and manipulate unique material properties. It is a common understanding that rubber's key characteristics include:

- High tear and tensile strength

- Dampening impact forces

- High flexibility

- Resilience

- Resistance to abrasion, high friction and low water swell

However, there are also other materials that could be investigated for this type of application such as; wood, plastic and steel. These materials host a wide range of beneficial properties and characteristics such as lightweight, crushable, high-strength and can be easily manipulated into different structures. On the other hand, these specific materials have disadvantages such as:

- Material properties of crushing wood can change from one piece to another depending on type of tree and supplier

- Wood does not respond well to weather and temperature changes

- Steel springs can often be too soft for this application

- All three materials are destroyed after a single use, increasing the overall cost by having to replace often

Designing the optimal product

We are well aware that no material acts perfectly on it's own in such demanding environments. When designing a product that both solves impact load handling at the same time as offering low friction, it is essential to manipulate and combine materials to create the best product for application considering:

- Performance and durability

- Total cost (upfront and maintenance)

- Lifetime

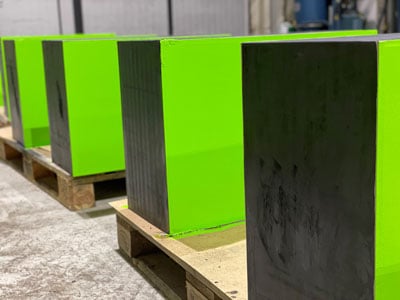

In similar cases, we have been able to design and manufacture elastomeric bearings using a mix of rubber, steel and plastic. This combination provides impact dampening during the connection process between the transition piece and monopile. It also offers low friction during the sliding and positioning of the transition piece after it has been placed on the monopile.

In similar cases, we have been able to design and manufacture elastomeric bearings using a mix of rubber, steel and plastic. This combination provides impact dampening during the connection process between the transition piece and monopile. It also offers low friction during the sliding and positioning of the transition piece after it has been placed on the monopile.

The elastomeric bearings serve the function of shock and impact absorbers, allowing installation to occur around the clock, in any harsh condition, without the fear of the heavy loads causing damage during this challenging process in demanding environments.