When it comes to tunnel construction, one of the most critical considerations is the piping system...

Steel Versus Rubber for Offshore Piping systems

Offshore topside structures must be designed for safety, reliability, and longevity in order to protect personnel and equipment. The choice of piping system can be a crucial decision for any offshore oil and gas topside structure.  Steel and rubber are two common materials used for piping systems in offshore topside structures, but each has its own advantages and disadvantages.

Steel and rubber are two common materials used for piping systems in offshore topside structures, but each has its own advantages and disadvantages.

As experts in rubber-based flexible piping systems, our team of engineers have a wealth of experience working with customers across the world to design, manufacture and deliver firewater deluge systems to unique specifications.

In this blog, we will compare the two materials to help you decide which one is best for your project.

Steel Piping

Steel piping systems are know to withstand the harsh conditions of offshore oil and gas topside structures. Steel piping systems are also understood to be corrosion-resistant, making them ideal for use in corrosive environments. However, the extent of which steel is corrosion resistant can be argued as in most cases, an additional material system is needed to ensure the corrosion resistance such as paint, rubber lining or sprays. This not only increases installation time but can have an impact on short and long-term cost.

Steel piping systems are also able to handle high-pressure applications, making them suitable for a variety of applications such as water injection, produced water, and firewater systems. However, these systems are relatively timely and costly to install and maintain due to hot work, operational downtime and limited corrosion resistance in such challenging conditions.

Another consideration towards steel piping systems, are the limitations of the velocity of the media flowing inside the pipe. Subject to type of steel material, typically the design-velocity is 3-7m/s to avoid adverse effects such as cavitation and internal erosion. In many instances, the only way to achieve this is to increase the pipe diameter and ultimately the overall weight and cost of the installed system.

Rubber-based Piping

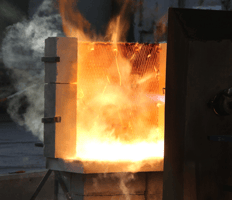

On the other hand, rubber piping systems offer all that steel can and are more flexible, which is ideal for use in areas with congested space. Rubber piping systems are also generally lighter than steel systems, making them easier to transport and install. Additionally, rubber piping systems are more resistant to adverse effects such as corrosion, marine growth, erosion, cavitation, vibration and shock, making them optimal for use in harsh and hazardous environments. We have found that our own rubber-based flexible piping system, Elastopipe is also more cost-effective than steel systems, making it an attractive choice for budget-conscious projects in the long-term.

When it comes to choosing a piping system for your offshore oil and gas topside structure, both steel and rubber have their advantages and disadvantages. Steel piping systems offer a good level of durability and short-term cost effectiveness, while rubber piping systems offer flexibility, reliability and long-term cost-effectiveness. Ultimately, the choice of piping system will depend on the specific material requirements and budget of your project.

Contact us with any questions if you would like to discuss a specific need for your upcoming project.